As is known to all, insulating glass has played a dominating role in the current market. However, its position is continuously challenged by vacuum insulated glass in recent years. Vacuum insulated glass has demonstrated superior performance far beyond insulating glass. What advantages does vacuum insulated glass have over insulating glass? Let’s take a close look.

1. Heat transfer mechanism: Vacuum insulated glass has better performance in thermal insulation

There are three types of heat transfer existing in the central area of a vacuum insulated glass: transfer through radiation, spacer, and residual air. For a quality vacuum insulated glass product, heat transferred through residual air is negligible. In comparison, insulating glass transfers heat through both air (conduction and convection) and radiation.

2. U-value: Low-E vacuum insulated glass is more cost-effective

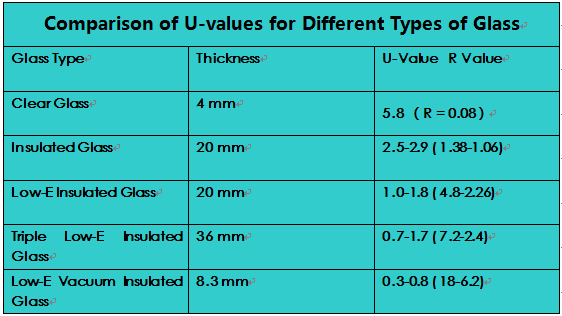

At present, there are only two kinds of exterior window glass that meet the low U-value criteria: triple-pane insulating glass and vacuum insulated glass: triple-pane insulating glass and vacuum insulated glass. As is shown in the table below:

Compared with the regular insulating glass, the U-value of Low-E insulating glass decreases noticeably;

For triple-pane insulating glass, using three pieces of Low-E coated glazing does not show many advantages over only one piece with Low-E coating in U-value.

In the meantime, the maximum Low-E of vacuum insulated glass is roughly the same as the minimum U-value of triple-pane insulating glass.

3. Installation positions: Vacuum insulated glass can be installed on the inclined roof or flat skylight

Insulating glass usually has its interspace filled with gas. When installed horizontally, its U-value rises due to the increase of gas convection. In comparison, vacuum insulated glass contains no air between the glass panes. U-value remains constant regardless of the position of installation.

4. Thickness and weight: Vacuum insulated glass is thinner and lighter

Provided that the U-values are similar, vacuum insulated glass will be 8.3 mm thick and weighs 22kg/m² while insulating glass will have a thickness of 36mm and weighs 34kg/m². As such, in comparison to insulating glass, vacuum insulated glass can significantly reduce buildings’ load-bearing and cost for framing materials. In addition, vacuum insulated glass is ideal for retrofit of old buildings. Without replacing the window frames, the renovation can be easily accomplished by changing the window glass directly or adding an inner layer.

5. Noise Isolation: The noise isolation performance of vacuum insulated glass in mid to low-frequency range is far better than insulating glass

In general, urban noises consist of domestic noise, traffic noise, occupational noise, and construction noise mostly in the low frequency (200Hz~300Hz) and mid-frequency (500Hz~1000Hz) ranges. The Weighted Sound Reduction Index of vacuum insulated glass is 36dB. Sound is transmitted mainly through spacers. The Weighted Sound Reduction Index of insulating glass is 29dB with the sound being transmitted through the air. It indicates that vacuum insulated glass is perfect for buildings in the downtown area or near streets.

6. Anti-condensation Performance: Vacuum insulated glass demonstrates great resistance to internal condensation

Condensation refers to the phenomenon where condensed water droplets form on the surface of an object when its temperature drops below the dew-point. As the vacuum insulated glass has its edges sealed all around, the vacuum chamber eliminates the possibility of condensation and keeps the glass surface temperature of the indoor side above the dew-point. For instance, in an environment where the indoor temperature is at 18℃with with relative humidity at 60%, the dew-points on the inner surface of insulating glass and vacuum insulated glass are -8℃and -36℃, respectively. It makes the vacuum insulated glass more suitable for applications in regions with extremely cold weather.

Depending on the quality of the butyl rubber sealant used in the sealing process, the insulating glass may have water vapor left in the chamber that cannot be removed and cause a negative effect in actual use. On the contrary, vacuum insulated glass will not encounter such a problem thanks to its vacuum chamber.

7. Application at various altitudes: Vacuum insulated glass can be used in regions at different altitudes.

Insulating glass manufactured at a low elevation will expand when it gets transported to regions at high altitude. However, vacuum insulated glass keeps no air between the panes and will certainly not have an expansion problem when it is installed in a high elevation location. As a matter of fact, vacuum insulated glass experiences less pressure difference at a higher altitude, therefore, less stress. This leads to higher safety.

8. Reduce “cold radiation” of surface: Vacuum insulated glass has a much higher surface temperature than other types of insulating glass

"Cold radiation" refers to the harmful radiation emitted by the cold walls of the human body. The poorer the insulation performance of glass, the lower the temperature of the indoor glass surface. Consequently, the more health risk the “cold radiation” will bring to us. The surface temperature of vacuum insulated glass is only 2-5℃ lower than room temperature and much higher than other glass under the same conditions.

9. Sealing performance and useful life: Vacuum insulated glass has a longer life than other glass.

Insulating glass commonly employs a dual-sealing structure with metal spacers. The inner layer of sealant is made of butyl rubber covered by an outer layer of silicone or polysulfide sealant. These materials age easily. In comparison, most vacuum insulated glass is sealed with solder glass and can last much longer. In general, the average service life of insulating glass is about 15 years, while vacuum insulated glass can serve more than 25 years.